Emergency Stop Due to a Safety Breach #

Upper safety Sensor breach: If the upper safety Sensor sensors detects a breach, the operator is required to empty the upper part of the system by completing the following steps:

- Please take down the wall and take out all vials from the machine! Then, take out the glass partitions. When handling the glass partitions, handle them carefully and utilize caution. When setting the glass on a surface, gently place it down on the long edge.

- Please take out all vials from the machine and close the wall

Make sure to take all vials from the storage, flippers, shakers, and Vial Gripper. Then, take

out the glass partitions. The system checks the sensors automatically and follow the cleaning

instruction if needed. - Please wait for the system to be ready. Vial insertion safety Sensor breach: If the breach happens while the Vial Robot is in the tray area, the robot will reposition to a safe location away from the user, and take another picture.

Syringe door safety Sensor breach: If the syringe door safety Sensor sensor detects a breach, the following message will appear: Robots will start moving now. Do you want to continue? Press OK, and close the syringe door. Now, the magazine will be scanned and the main menu will reappear on the screen. NOTE: If there were any preparations while the breach occurred, they will be canceled and returned to the preparation list.

Emergency Stops and Electrical Surges #

If necessary, in order to urgently stop the system, use the RED Emergency Stop button which is easily accessible on the main panel located on the arm of the Touchscreen HMI.

NOTICE!!! Following an emergency stop (electrical system shutdown), an electrical surge, or during an electrical power outage, all processes will be canceled and the the operator will be required to empty the system. The The following steps elaborate on the process of how to empty the EQUASHIELD® Pro.

After pressing the button, the following messages will appear:

- Please release the Emergency Stop Button to resume Release the button by turning it right.

- Please take down the wall and take out all vials from the machine!

Take out the glass partitions. - Please take out all vials from the machine and close the wall

Make sure to take all vials from the storage, flippers, shakers, and vial gripper. Then, take out the

glass partitions. When handling the glass partitions, handle them carefully and utilize caution. When setting the glass on a surface, gently place it down on the long edge. Then take out the glass partitions. The system checks the sensors. automatically. - In the event of an emergency stop, please wait for the system to be ready. In the event of an electrical surge, please reopen the EQUASHIELD® Pro application on the touchscreen. After the program finishes loading, please press the red Emergency Stop button on the

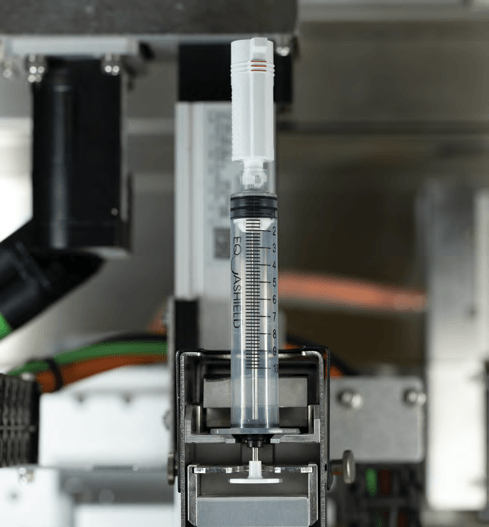

right arm. - The cabinet doors will open now. Please empty the pumps and close the doors! – empty syringe units only from the pumps and not from the magazine (figure 10) and follow cleaning instructions if needed Please close the door in order to resume.

- Robots will start moving now. Do you want to continue? Press OK.

- Please wait while recovering! Now the system performs a homing process for all the mechanical

equipment in it. The infusion bags should be removed from the Bag Bases. - When recovery is complete, the main screen will reappear and all prescriptions will once again be ready for preparation.

Failure to Release IV Bag from Compounding Station #

If the EQUASHIELD ® Pro fails to release the IV bag, please ensure the following:

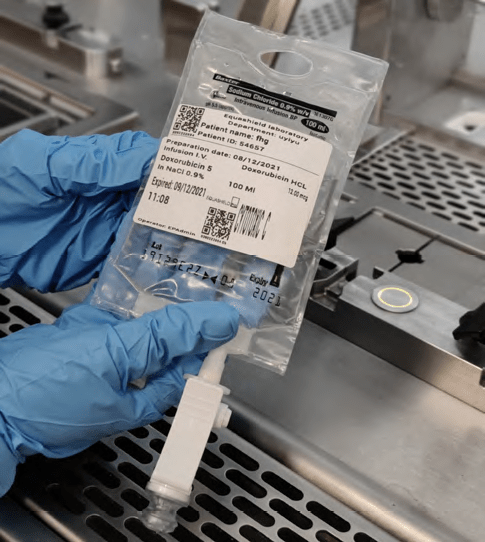

- Check that the operator placed the correct validation Finish Sticker on the correct preparation.

- Ensure that the QR codes on the initial preparation sticker and Finish sticker are not accidentally covered and are legible.

- Reposition the IV Bag to assist the camera to capture the 2 QR codes.

- Press the corresponding button next to the station again.

Hazardous Drug Spill #

In case of hazardous substance spillage, stop the operation and follow the spillage handling

procedure, described in the Cleaning Procedure SOPR-M-221.

Syringe Unit and/or Vial Drop #

In the event that a syringe has been dropped from a Pump Robot or a vial has been dropped from the Vial Robot, the system will perform a recovery procedure.

The user will have to follow the instructions that will appear on the screen. Note that the Pump robot will only perform a recovery if the syringe unit was dropped more than once. If the problem persists, please contact technical support.

FFU Performance #

The laminar flow of the cabinet is facilitated by 3 Fan Filter Units (FFU).

In case the FFU parameters reach their set limits, a warning will appear on the screen, later to be followed by a system shutdown.

Damper Controls #

The room’s damper controls the inflow and air withdrawal in the cabinet. In case parameters reach

their limits, the system will trigger an acoustic alarm.

Leaning, Weight, and Force #

Do not lean over the screen arm or the printer arm.

Do not apply force on the Vial Insertion Scale or the IV bag backlight, located next to the printer.

These units are equipped with load sensors, which can be damaged if exposed to excessive force.

Software Stops #

No software system is free of faults. Faults should not happen, but they can.

In case of a process stop due to a software stop, perform a system shutdown if possible.

If a shutdown is not possible, long-press the reboot button on the screen arm.

Delayed Response with Opening Operator Application #

It takes a second to open the application (after double-clicking).

Don’t keep clicking or it can cause some delay. Just double-click to start and be patient for it to open.