Introducing EQUASHIELD® Pro #

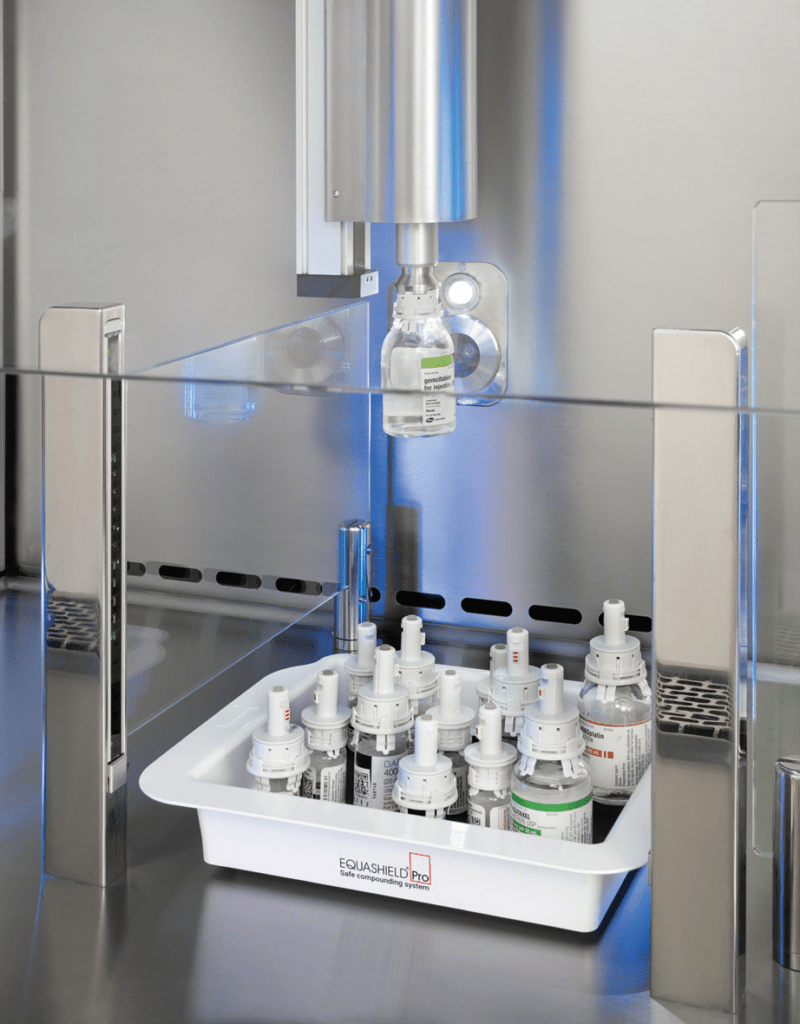

EQUASHIELD® is a developer of Closed System Transfer Devices (CSTDs) to safely handle hazardous drugs during compounding and administration. EQUASHIELD®’s mechanically closed CSTD design relies on its unique pressure equalization mechanism and its use of double tight seal double membranes to keep connectors residual-free despite multiple entries. EQUASHIELD® Pro is built around the EQUASHIELD® CSTD and relies on its innovative design to redefine the automation workflow and optimize throughput.

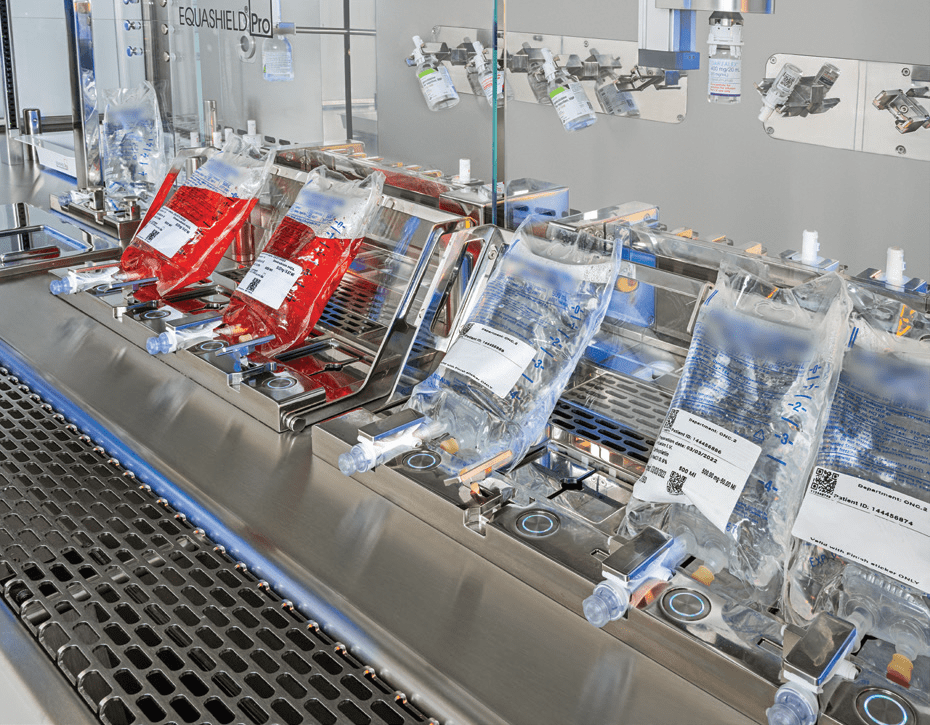

Unlike traditional robot’s reliance on robotic arms that mimic human motion with the use of conventional needle and syringe methods, which may potentially lead to cytotoxic drips, spills, aerosols, and vapor release, EQUASHIELD® Pro uses a multi-station compounding approach to minimize both the motion and time it takes to prepare a dose, much like a factory manufacturing line. EQUASHIELD® Pro can also process a wide variety of finished product dosage forms and access all-size drug vials to be a truly versatile machine. EQUASHIELD® Pro is designed to make the adoption of robotics simple and affordable in the IV compounding workspace regardless of hospital size. It is comparable in size to a standard Biological Safety Cabinet, making it easy to fit into hospital pharmacies.

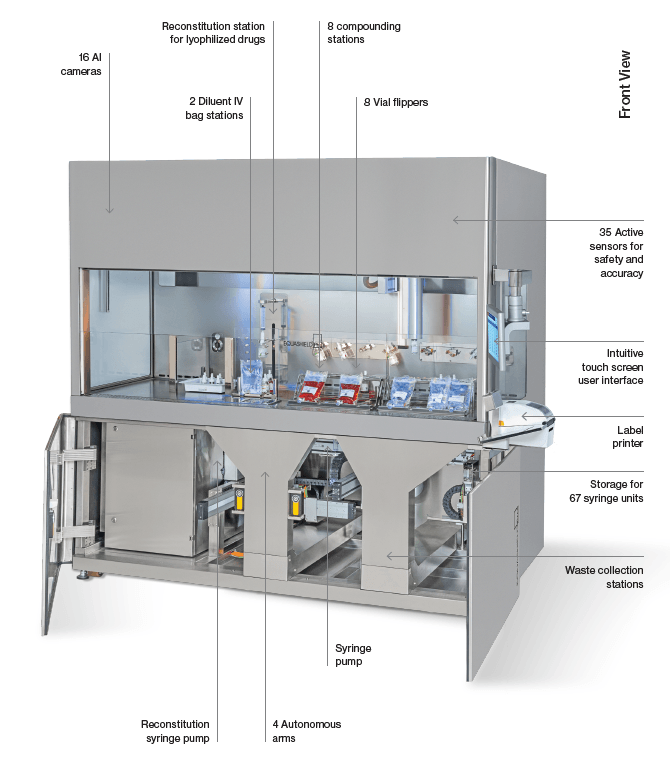

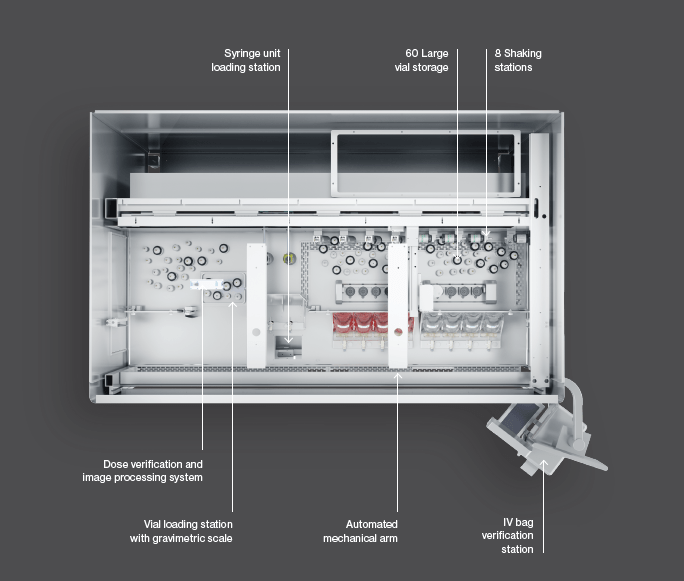

A Look Inside EQUASHIELD® Pro #

A Game-Changing Approach to Automated Drug Compounding #

EQUASHIELD® Pro is changing the automated compounding industry in the same way that EQUASHIELD® revolutionized the CSTD standard.

As a leader in the field, EQUASHIELD® Pro provides unprecedented safety, efficiency, and accuracy.

Safety #

Utilizing our CSTD, EQUASHIELD® Pro is the only automated compounder with a truly closed system from start to finish of the compounding process. The safety of the CSTD extends to the administration process by providing the pharmacy and nursing staff with a fully-closed final product free of exposure to hazardous drugs.

EQUASHIELD® Pro has the built-in safety of the industry-leading closed transfer device system.

This ensures the highest level of safety by preventing the risk of exposure to leaks or vapors.

Efficiency #

The EQUASHIELD® Pro is designed to complete a daily workload in one hour with unprecedented throughput. Since the EQUASHIELD® Pro can compound multiple patient-specific preparations simultaneously, the production rate is significantly faster. This yields higher productivity in the pharmacy with manufacturing capabilities.

High throughput meeting your compounding needs during peak time, enabling you to optimize patient care without sacrificing resources.

Accuracy #

Even with increased throughput, the accuracy of the dose preparation is never compromised. EQUASHIELD® Pro uses advanced image processing and provides real-time analytics for the monitoring and management of dose preparation. With the assistance of artificial intelligence, there is constant oversight and safety checks throughout the preparation process validating every stage. The imaging and information from the validation processes are archived and can be utilized for documentation.

Dosage error protection uses EQUASHIELD®’s dose verification system to prevent drug errors, dose mixing, and labeling errors during compounding.

Software #

The EQUASHIELD® Pro software is designed with the end user in mind. The software is compatible with HL7 or REST standards for complete integration with the facility’s information and prescribing system. EQUASHIELD® Pro software protects patient information and facility data.

The EQUASHIELD® Pro application and touchscreen are interactive and intuitive with prompts that guide the operator during the compounding process. Also, the EQUASHIELD® Pro prescription reports and images can be archived for reference and documentation purposes.