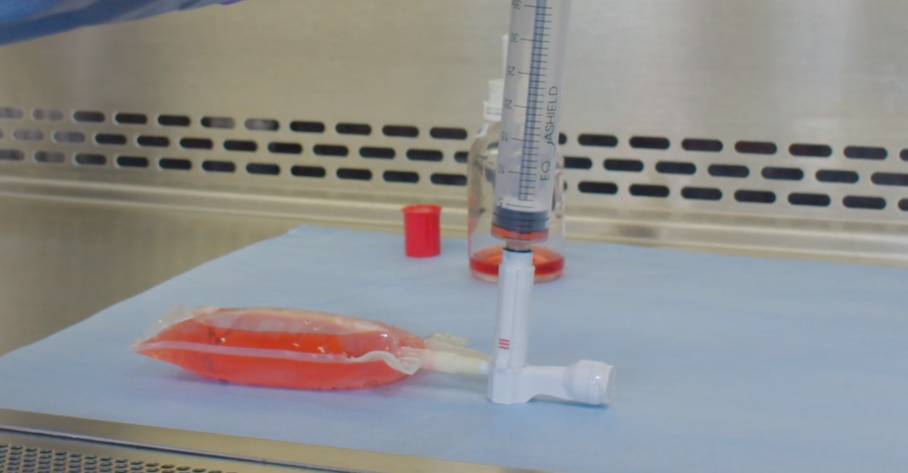

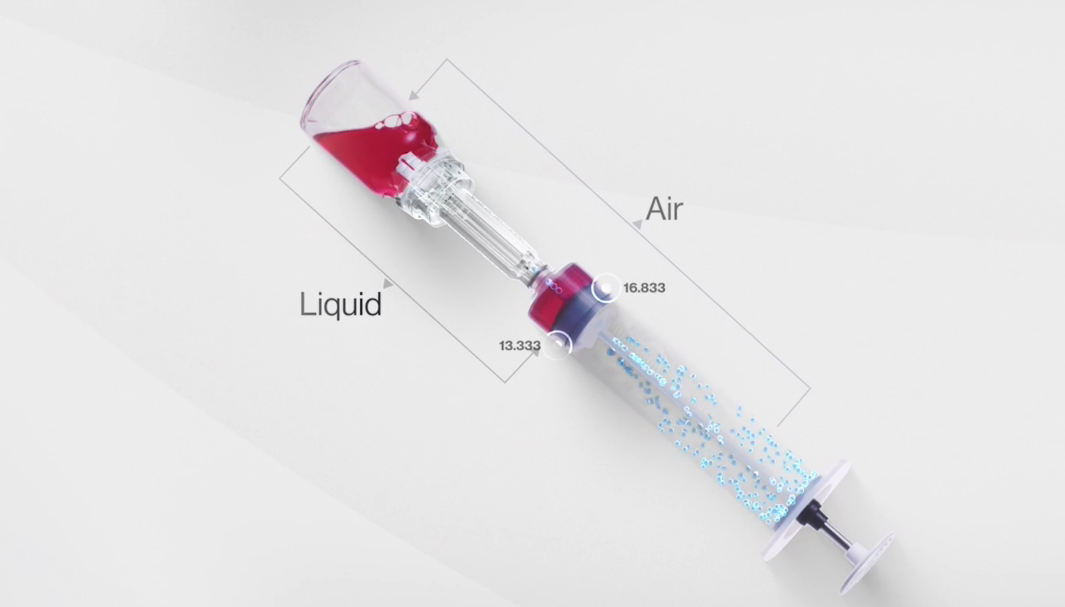

EQUASHIELD® Syringe Units maintain a closed pressure equalization that prevents the escape of vapors and aerosols during compounding and administration. A unique dual-needle, air-to-liquid exchange system, combined with a closed-back sterile air chamber behind the syringe, ensures that pressure is equalized throughout the hazardous drug handling process.

Protecting from plunger rod contamination and release of hazardous vapors from the back of the syringe. The EQUASHIELD® equalizes pressure differentials via a dual needle design, enabling an efficient air to liquid exchange. The Syringe Unit contains sterile air that is drawn from the sealed air chamber at the back of the syringe, requiring no additional steps to equalize pressure.

EQUASHIELD® Syringe Units maintain a closed pressure equalization that prevents the escape of vapors and aerosols during compounding and administration. A unique dual-needle, air-to-liquid exchange system, combined with a closed-back sterile air chamber behind the syringe, ensures that pressure is equalized in a system throughout the hazardous drug handling process.

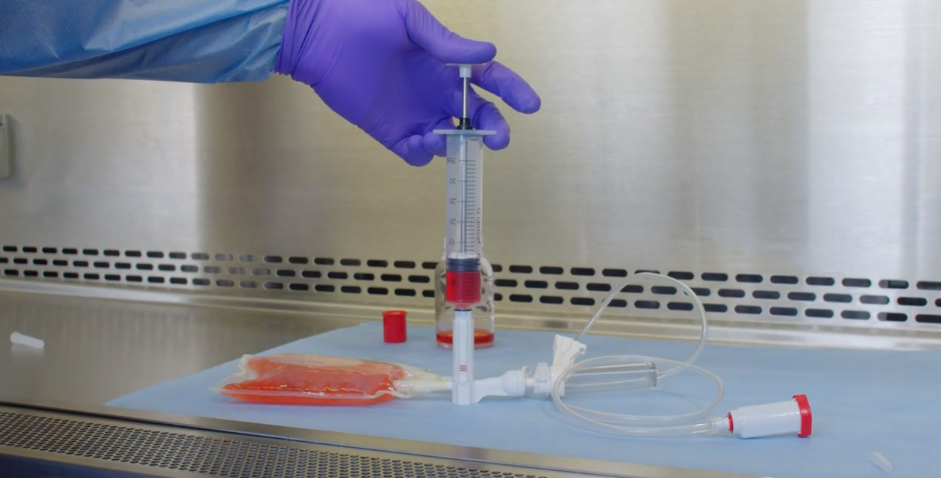

EQUASHIELD®’s fully encapsulated Syringe Units prevent the exposure to syringe plunger and barrel contamination caused by hazardous drug handling. The system is equipped with a built-in closed pressure equalization with sterile air. The connector is permanently bonded onto the syringe body preventing accidental disconnections and houses the shielded needles to prevent the risk of accidental needle sticks.