Safeguarding Cell / Gene Therapy Manufacturing

CellSHIELD is an IP-protected fully closed device ensuring sterility throughout the cell / gene therapy manufacturing process. The product empowers biopharma companies and CDMOs alike to safely and efficiently scale-up manufacturing operations – often eliminating the need for a biosafety cabinet.

/ 01

/ 02

/ 03

/ 04

Years of Experience

Countries

Employees

Global Customers

Prevents release and ingress of extraneous biological agents and microbes.

No cross-contamination risk.

To vapors or disinfectants. Compatible with cleanroom disinfectants via liquids or vhp.

Clinically-validated.

No wastage during sampling… and every single dose is crucial.

Device suited for sampling mammalian cells & cell transfer without impacting cell viability.

High assurance of zero defects at point-of-use.

Quality Control

Therapy Manufacturing

Input Manufacturing

Discovery & Development

CellSHIELD™ offers a user-friendly and intuitive experience, requiring minimal training. This streamlines the onboarding process for newly-hired employees, allowing them to quickly adapt and contribute to the workforce.

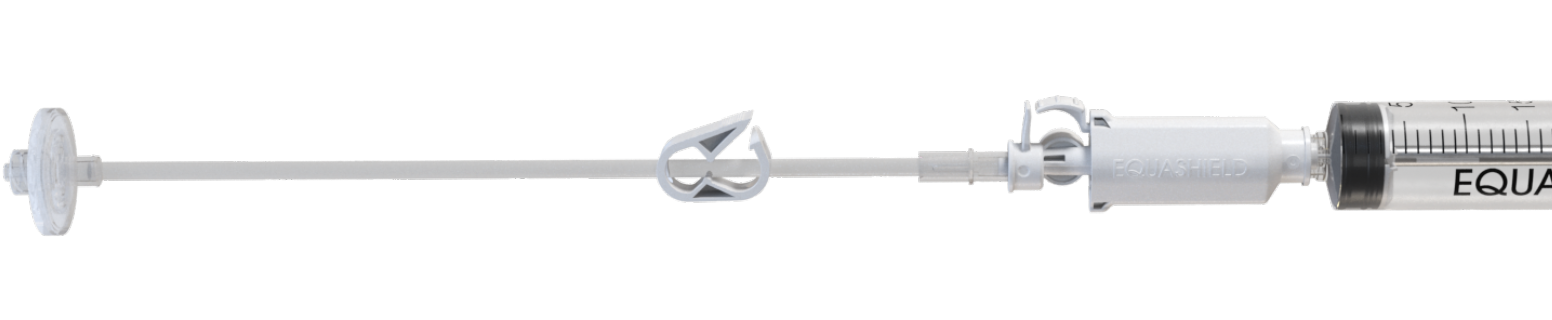

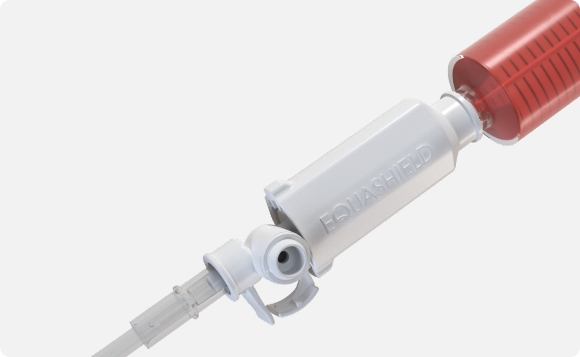

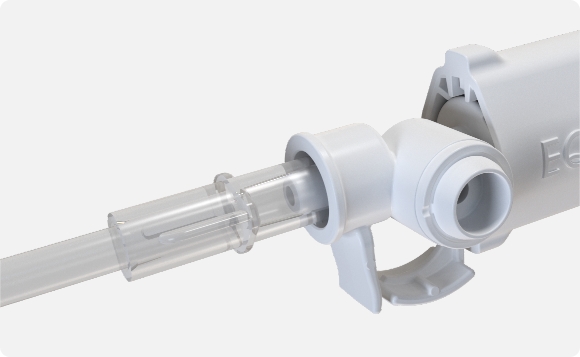

Fully encapsulated structure prevents syringe-plunger detachment and contamination; enables the device’s pressure equalisation system.

Air released to make way for the cell mixture flows through a needle in the syringe center and ultimately passes through a hydrophobic filter.

When the media is ultimately released from CellSHIELD™, incoming air passes through the filter to maintain sterility; the filter also allows EtO gas to pass through originally, before any product usage.