Current State of Pharmacy Compounding Automation

In the rapidly evolving landscape of healthcare, the realm of pharmacy is undergoing a transformative shift with the advent of compounding automation. This paradigm shift is revolutionizing the way pharmacies function in the United States, leading to enhanced efficiency, improved accuracy, and increased safety. Pharmacy compounding, once a labor-intensive process requiring meticulous manual effort, is now becoming an automated operation, harnessing cutting-edge technology to streamline workflows and mitigate potential errors. This article delves into the current state of pharmacy compounding automation in the U.S., exploring its benefits, challenges, and the potential it holds for the future of pharmaceutical care. From reducing the risk of cross-contamination to ensuring precise dosage and formulation, automation is poised to redefine the standards of pharmacy compounding, making it a compelling topic of discussion in contemporary pharmaceutical discourse.

What are the main challenges?

Pharmacy compounding automation, while offering numerous benefits, does present its own set of challenges. The initial cost of adopting automated systems can be substantial and may deter some pharmacies, particularly smaller operations. Additionally, implementing these systems requires a significant amount of training and adaptation for the staff, potentially disrupting workflow during the transition period. Interoperability issues, where different systems fail to communicate effectively with each other, can also pose a challenge. However, the market is evolving rapidly to meet these challenges head-on. Numerous companies are developing more user-friendly interfaces, comprehensive training programs, and better integration capabilities to ensure smooth operation. Meanwhile, the long-term savings in terms of time, reduced wastage, and improved accuracy often outweigh the initial investment, making automation an increasingly viable option for pharmacies of all sizes.

Pharmacies play a critical role in providing safe and effective medications to patients. However, a study suggests that approximately 9 percent, or nearly 1 in 10, of IV preparations may contain errors, with the most common problem being incorrect ingredients and/or volumes. These errors have the potential to cause harm or even result in patient fatalities1. One area where advancements in technology can significantly improve safety and efficiency is the pharmacy compounding process. By leveraging artificial intelligence (AI), pharmacies can streamline their operations while minimizing the risk of errors. This blog post will discuss how AI can help reduce human error and enhance accuracy and consistency in pharmacy compounding, as well as the essential role of Closed System Transfer Devices (CSTDs) in maintaining a contamination-free environment.

Harnessing AI to Reduce Human Error in Pharmacy Compounding

The integration of AI technology into pharmacy compounding processes offers several benefits, including:

- Precision and Consistency: AI algorithms can precisely measure and dispense drug components, ensuring consistency and accuracy in the final product. This reduces the likelihood of dosage errors reaching the patient2.

- Real-time Monitoring: AI-driven systems can continuously monitor the compounding process, detecting and correcting errors before they become a threat to patient safety.

- Data Analysis and Learning: AI can analyze historical data to identify trends and patterns, enabling continuous improvement in the compounding process and reducing the risk of future errors.

While AI is already making a significant impact, its potential in the field of pharmacy is far from fully realized. Future developments could see AI being used to automate more complex tasks, further reducing the burden on human pharmacists and minimizing the risk of errors. For instance, we could see AI systems that can interpret complex prescription orders or even dispense medications autonomously.

By adopting AI-driven automation, pharmacies can significantly reduce the occurrence of human errors, leading to safer and more efficient compounding processes.

The Role of Closed System Transfer Devices (CSTDs) in Ensuring Safety and Sterility

While AI can greatly improve the accuracy and consistency of pharmacy compounding, maintaining a sterile and contamination-free environment is equally important. Closed System Transfer Devices (CSTDs) serve as an additional layer of protection against contamination, particularly when handling hazardous drugs.

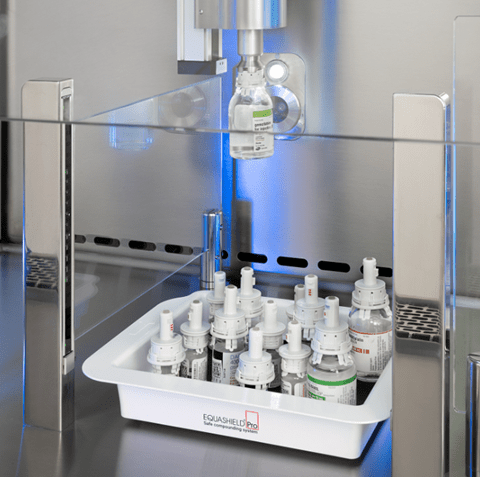

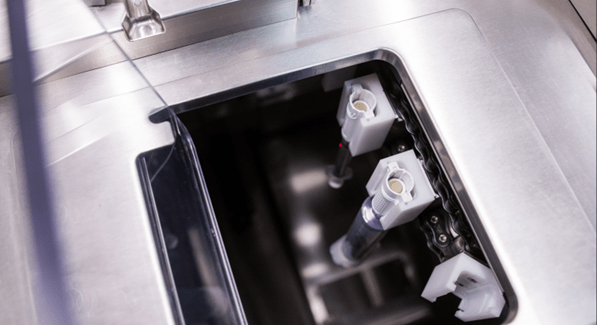

CSTDs are specially designed drug-transfer devices that create a physical barrier between the drug, the environment, and healthcare workers. They are used to prevent the escape of hazardous drug vapors, aerosols, and droplets during compounding and administration3. By incorporating CSTDs into the pharmacy compounding process, pharmacies can:

- Minimize Exposure Risks: CSTDs reduce the risk of healthcare workers and patients being exposed to hazardous drug particles, ensuring a safer working environment.

- Maintain Sterility: CSTDs help maintain the sterility of compounded medications by preventing contaminants from entering the drug preparation process.

- Complement AI-driven Systems: The integration of CSTDs with AI-driven automation systems can provide comprehensive protection against both dosage errors and contamination risks.

Embracing AI and CSTDs for a Safer Future in Pharmacy Compounding

By integrating artificial intelligence technology and Closed System Transfer Devices (CSTDs) into their compounding processes with products like the EQUASHIELD Pro, pharmacies can significantly enhance safety, efficiency, and accuracy. This powerful combination of cutting-edge technology and robust protective measures can help minimize the risk of medication errors, ensuring optimal patient care and public health outcomes.