AI has been heralded as the future of production lines, providing a level of automation and control that is unparalleled- surpassing limited human visual perception by employing advanced image processing techniques. At EQUASHIELD, we take pride in our early adoption of AI technology. We have seamlessly integrated it into our automated warehouse, production lines, and packaging. This results in enhanced efficiency, improved product quality, and reduced waste.

The use of AI in the production lines at EQUASHIELD is an integral part of our success. The AI system ensures constant quality control and provides real-time status updates for each product throughout the automated assembly process, thanks to the integration of over 300 cameras across 500 stations. Cameras and sensors play a crucial role in facilitating the automated machine operations by providing valuable data including orientation, barcode reading, OCR (Object Character Recognition), and defect detection. This ensures a high level of consistency and accuracy in the production process, reducing costly errors, and minimizing the need for manual labor.

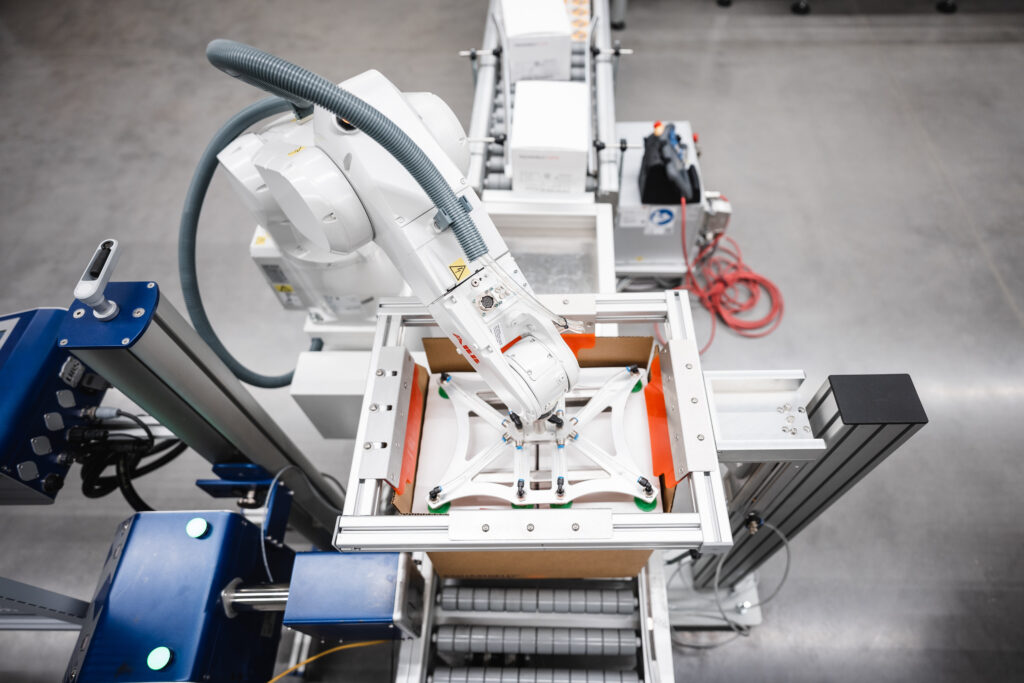

Revolutionizing Product Tracking and Packaging

Another one of the key benefits is the ability to extract vital information for product tracking and automatic packaging. The system reads UDIs (Unique Device Identification), prints checks, and conducts end-of-the-line blister checks to ensure that every product is flawless and ready for use. The cameras have superior zoom capabilities compared to the human eye, leading to enhanced flaw detection. This level of automation and quality control is crucial when it comes to medical products, where any flaw could have serious consequences for patient health.

Utilizing Predictive Maintenance to Reduce Waste and Save Time

At EQUASHIELD, the utilization of AI models is an ever-evolving process. We employ a wide range of models to enhance the image processing capabilities of our production lines. Predictive maintenance is another crucial application of AI. By collecting real-time data and employing data science algorithms, we can anticipate potential mechanical failures resulting from incorrect calibration of parameters such as temperature and torque resulting in reduction of production down time. Smart defect detection possesses a deep understanding of potential issues, promptly indicating and aiding technicians in resolving them effectively. As a result, the production lines considerably reduce product waste while identifying flaws in production. This has resulted in significant time and cost savings, as well as improved product reliability, customer satisfaction and retention.

By implementing automated quality control and real-time status updates, we ensure a consistent and accurate production process. Furthermore, the ability to extract crucial information for product tracking and enable automatic packaging adds an extra layer of quality assurance. With a range of AI models utilized in our production lines, we are at the forefront of the industry, continuously enhancing image processing capabilities and improving product quality. At EQUASHIELD we are proud to set a higher standard in the world of medical device manufacturing.

The use of AI in our production lines has a direct impact on the quality and reliability of our products. By ensuring constant quality control and reducing waste, we can confidently stand behind our products and guarantee their effectiveness for healthcare professionals. This level of precision and efficiency would not be achievable without the integration of AI technology, making EQUASHIELD a leader in revolutionizing medical device manufacturing. By continuously evolving and improving our production processes, we strive to provide the best possible products for the healthcare industry. So, our customers can have peace of mind knowing that they are using safe, reliable, and high-quality medical devices from EQUASHIELD.